Quality Compliance

Our commitment is to provide high quality products, which satisfy our customers’ needs and expectation by building quality in all our operation and to improve our process and systems.

Therefore we are committed to- Develop & maintain a vibrant work environment, which encourages employees’ involvement for self and organizational growth.

- Apply process for clean production, pollution prevention optimize resource utilization in all operations.

- Enhance productivity through technology & process that ensure quality at a competitive prices.

- Comply with applicable regulations and legislation

- We pledge to provide quality and safe products under clean and hygienic environment.

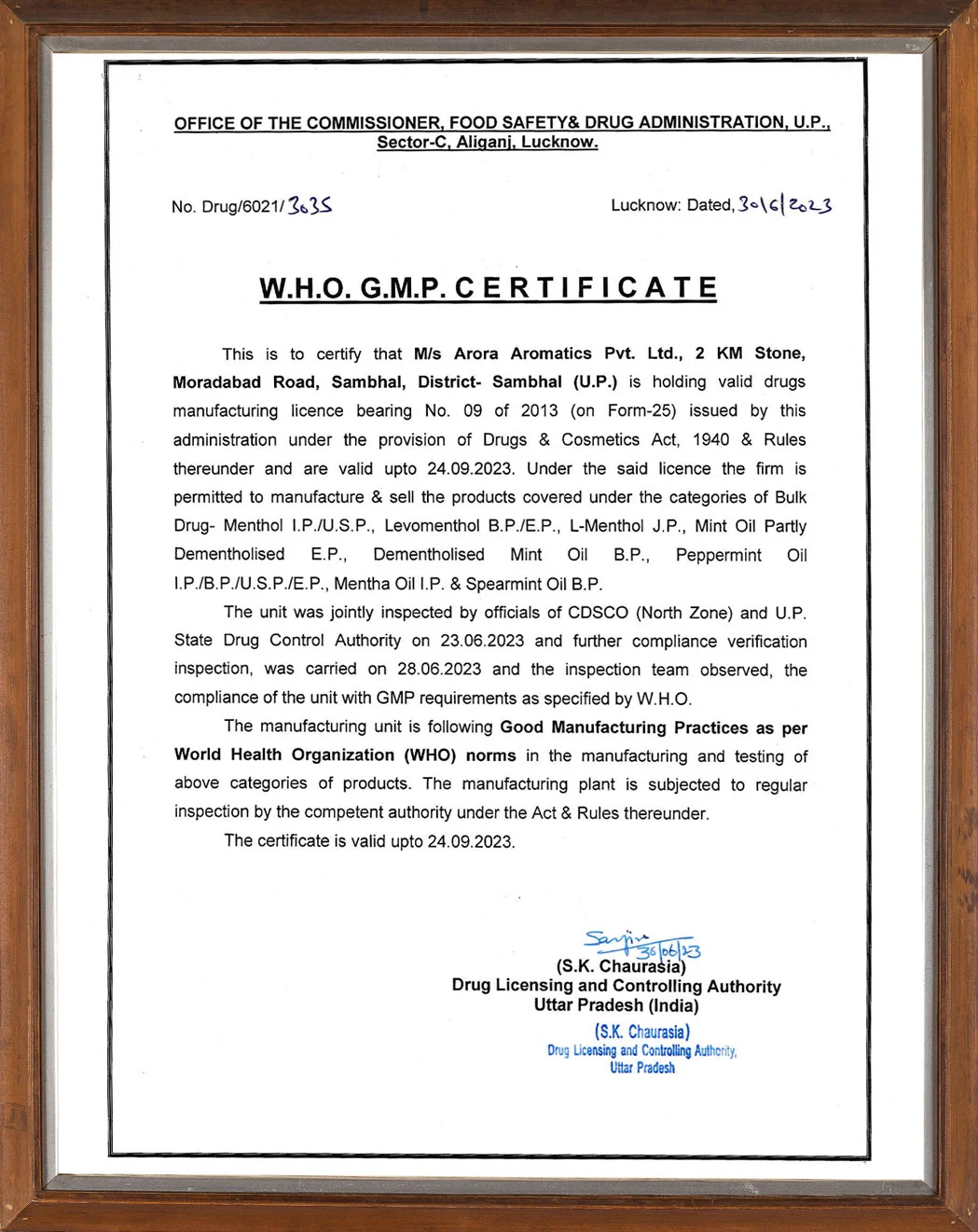

AAPL is employing best expertise to Pest & Rodent control, Equipment Calibration, Workers’ Health checkup and training programmes to all employees for their corresponding departments. Analysis of all the Raw material Intermediate and finished products is carried out at the site by our own trained quality control staff.

A well documented procedure is followed for selection of raw material suppliers. All the material used at the plant site is obtained from “APPROVED SUPPLIERS” only. Vendors supplying material are audited as per schedule and on need basis. QA department heads normally evaluates the performance of vendors.

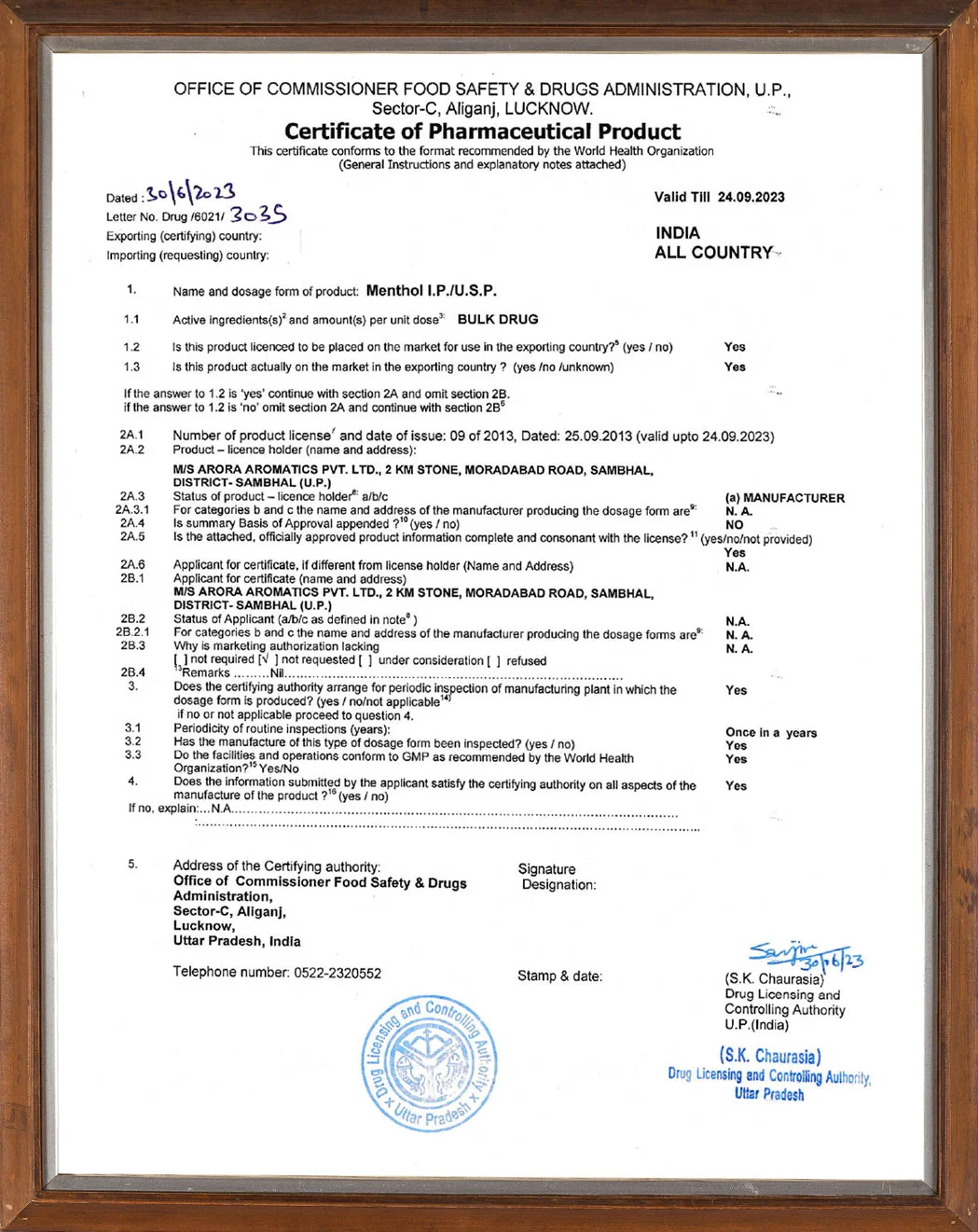

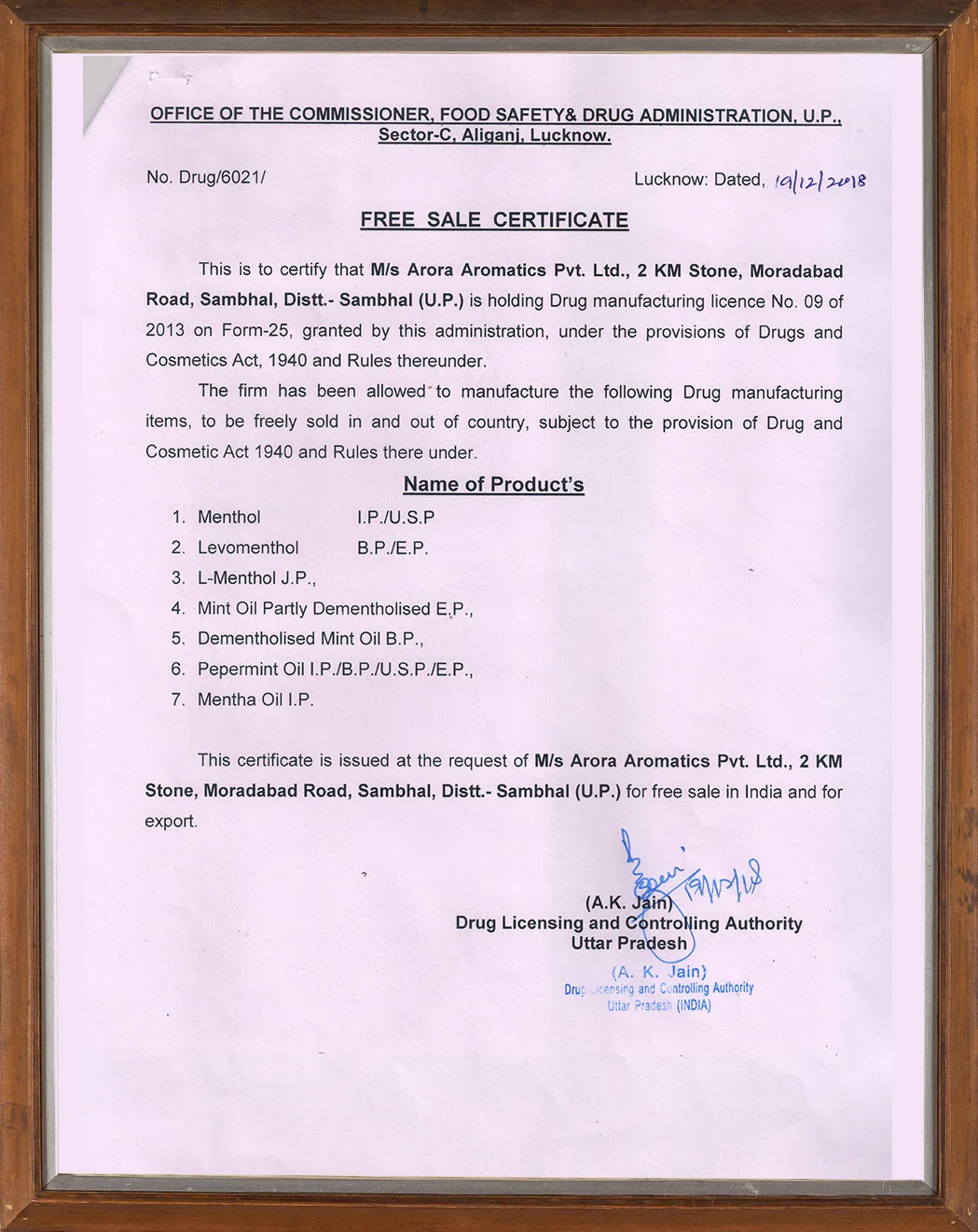

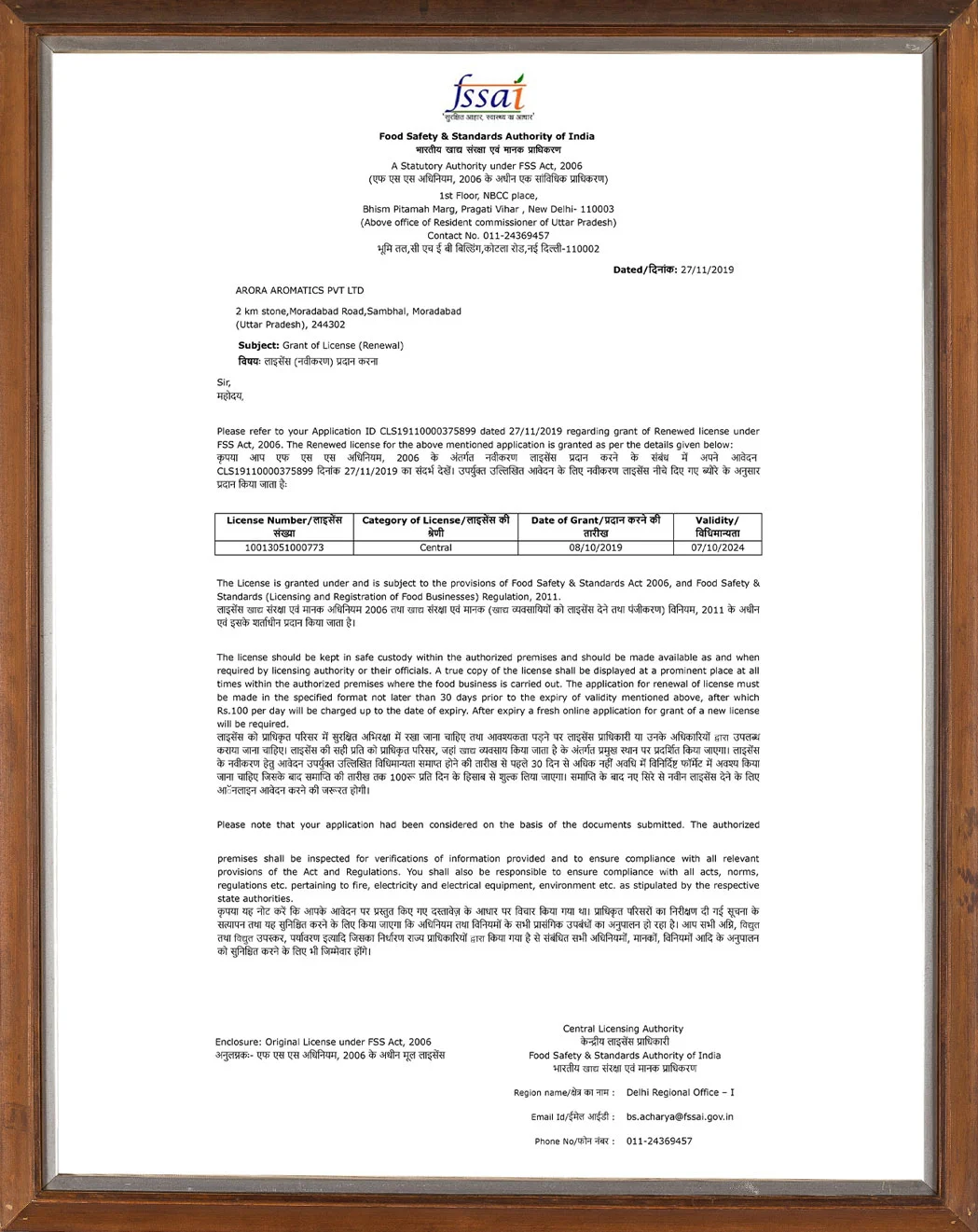

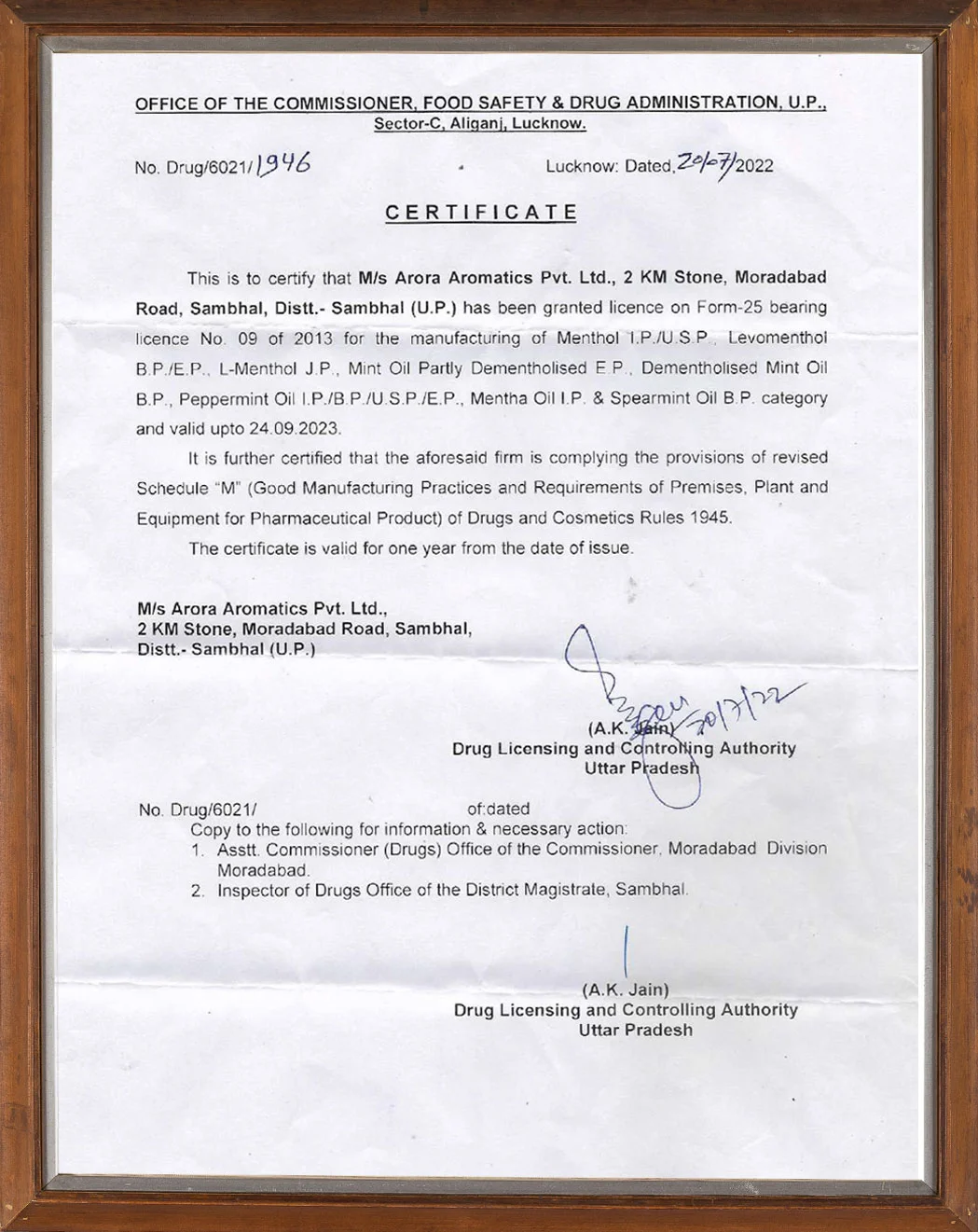

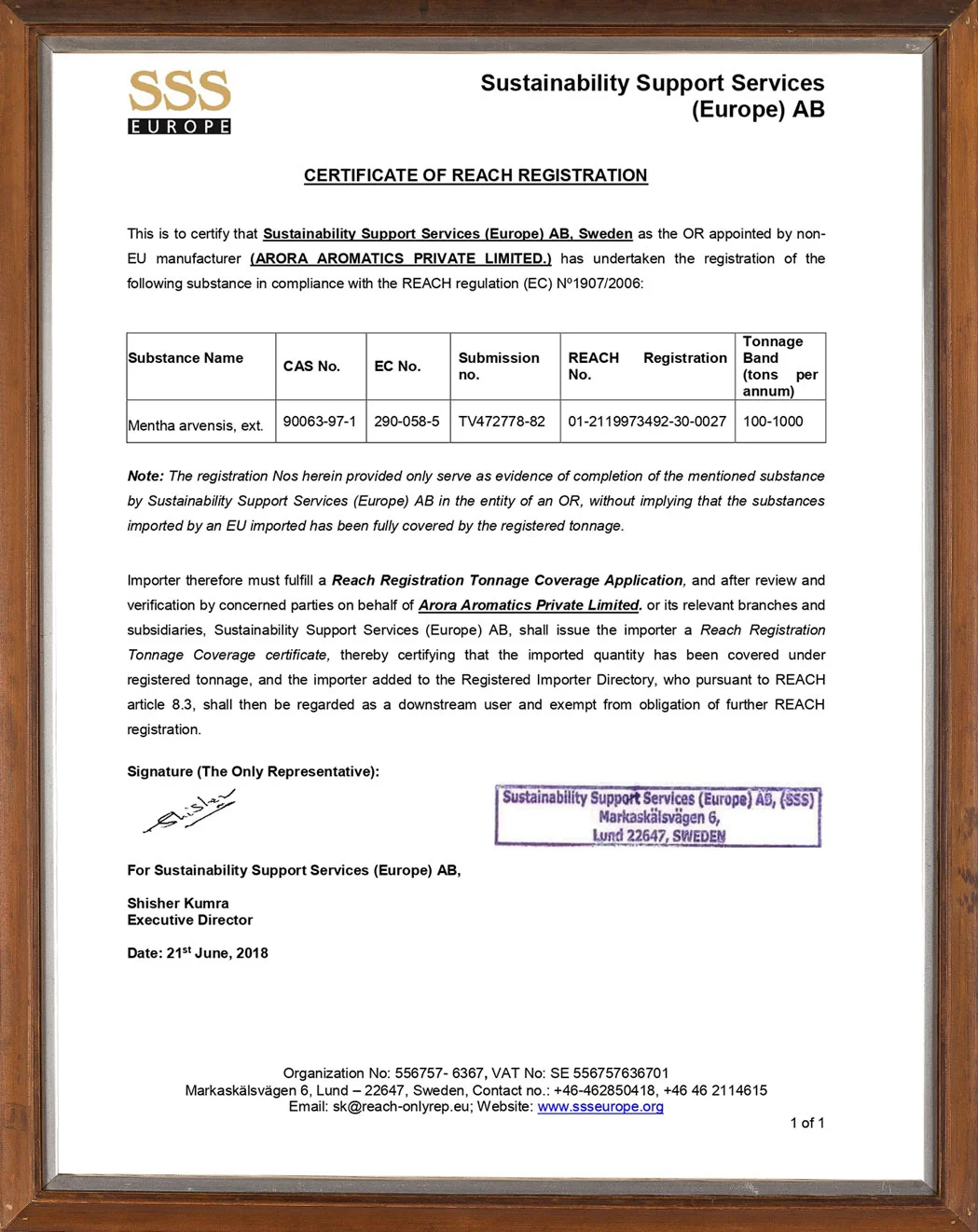

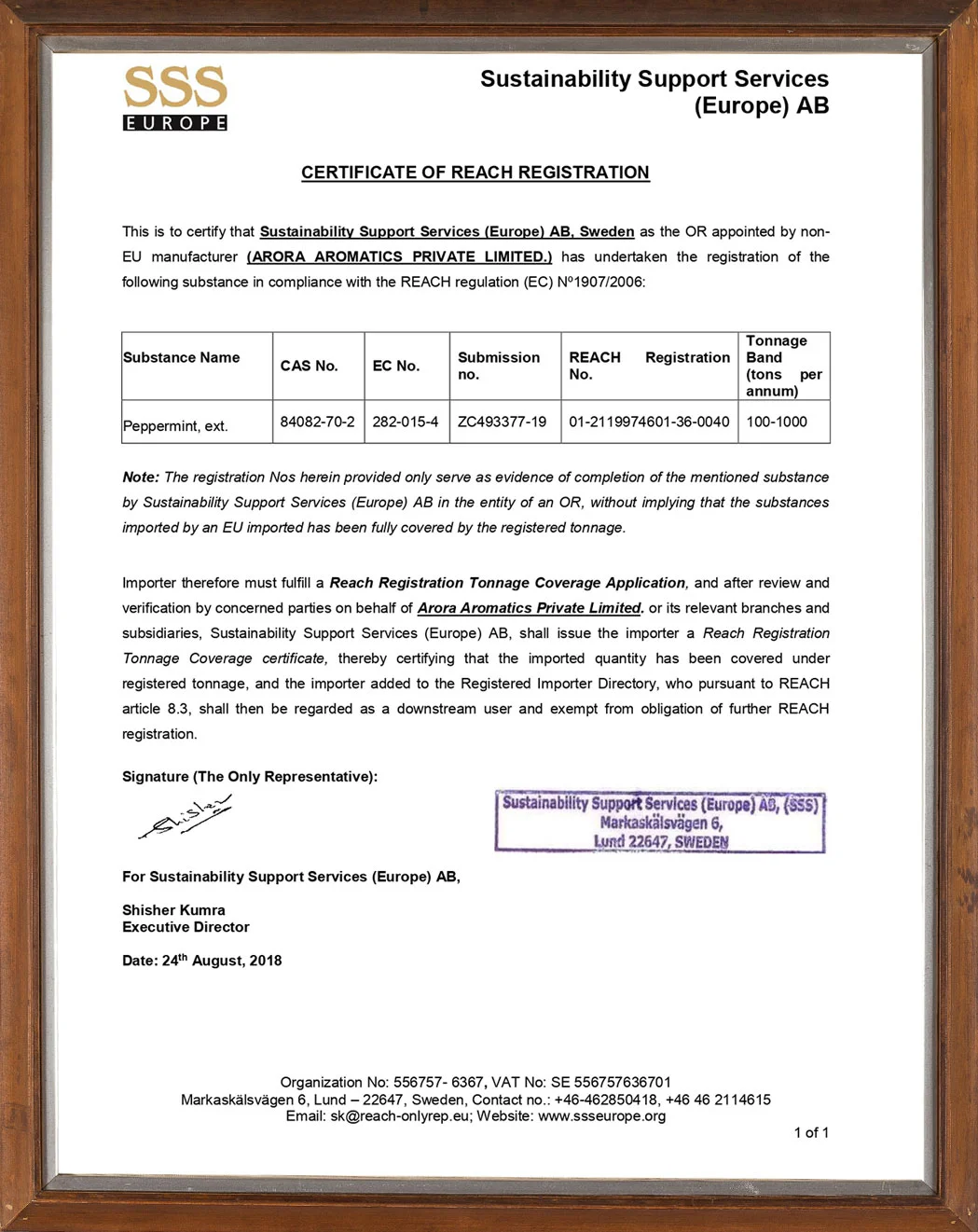

This site is licensed to manufacture pharmacopeia grade(Bulk Drugs) Mentha Oil-IP, Menthol-BP/USP, Menthol crystals-IP/BP/USP/EP, Peppermint Oil-IP/BP/USP/EP, De-Mentholated Peppermint Oil-IP/EP under the manufacturing license No.- 06, on Dated 17 September 2012 issued by Drug controller of Uttar Pradesh, India.

Leaders ate ASAPL are independently ensuring the quality of all plant functions. There are approved and sophisticated operating procedures for each activity carried out at site or in plant. Implementation of these procedures is the responsibility of the user, which is also monitored by a team of trained quality assurance officers. Release of a batch is based on the conformance of the intermediate/Finished products to the standard specification as well as review of the batch manufacturing records, batch packaging records and analytical reports by Quality Assurance department. After ensuring all these, QA department authorizes to release the products for sale dispatch.

Leaders ate ASAPL are independently ensuring the quality of all plant functions. There are approved and sophisticated operating procedures for each activity carried out at site or in plant. Implementation of these procedures is the responsibility of the user, which is also monitored by a team of trained quality assurance officers. Release of a batch is based on the conformance of the intermediate/Finished products to the standard specification as well as review of the batch manufacturing records, batch packaging records and analytical reports by Quality Assurance department. After ensuring all these, QA department authorizes to release the products for sale dispatch.

Self inspection by leaders is also conducted at the site at regular intervals besides that is done by external by regulatory authorities to conform the required standards. The audit report and the compliance report are documented by the quality assurance department.

An In-House laboratory equipped with modern facilities for Chemical, Instrumentation, and Stability Testing is being run by experienced competent and well qualified personnel. This lab is also equipped with an Instrumentation room, which is totally temperature controlled. Corresponding operating procedures (SOPs) are being followed for instruments used for the analytical purpose.

The lab is headed by a very experienced and knowledgeable person who ensures day to day quality control functions as applicable to bulk drugs & Aromatic Chemical manufacturing. He is also responsible for sampling and analysis done as per approved specifications. He is equally responsible for Release or Reject raw materials, packing material, intermediate products and finished products. However final release is approved by QA head.

In order to ensure that all machine and equipments running efficiently, a planned preventive maintenance is carried by the plant engineering department. Details procedures for preventive maintenance are available, which defines the frequency of preventive maintenance. The procedure includes the preventive maintenance check-list of all the machines and equipments. Records for preventive maintenance carried out are maintained. Few equipment/machine are serviced by outside agencies at agreed frequencies. Laboratory equipments are serviced or calibrated by outside agencies annually at fixed time. Records of preventive maintenance by external agencies are also maintained and regularly reviewed by QA managers. The production department has all the required equipments or machinery to carry out the activity of batch manufacturing and packaging. All equipments are cGMP compliant. Product contact part made of 304 & 316 L. It is also ensured that equipment design facilities complies easy cleaning and operations.

Copyright © 2023 Arora Aromatics Pvt. Ltd. | All Rights Reserved. Website Designed & SEO By Webclick® Digital Pvt. Ltd. Website Designing Company India.